Overview of Air Circuit breakers

Air-Blast Circuit Breakers

These breakers employ a high pressure *air-blast as an arc quenching medium. The contacts are opened in a flow of air-blast established by the opening of blast valve. The air-blast cools the arc and sweeps away the arcing products to the atomsphere. This rapidly increases the dielectric strength of the medium between contacts and prevents from re-establishing the arc. Consequently, the arc is extinguished and flow of current is interrupted.

Advantages.

An air-blast circuit breaker has the following advantages over an oil circuit breaker:

(i) The risk of fire is eliminated.

(ii) The arcing products are completely removed by the blast whereas the oil deteriorates with successive operations; the expense of regular oil replacement is avoided.

(iii) The growth of dielectric strength is so rapid that final contact gap needed for arc extinction is very small. This reduces the size of the device.

(iv) The arcing time is very small due to the rapid build up of dielectric strength between contacts. Therefore, the arc energy is only a fraction of that in oil circuit breakers, thus resulting in less burning of contacts.

(v) Due to lesser arc energy, air-blast circuit breakers are very suitable for conditions where frequent operation is required.

(vi) The energy supplied for arc extinction is obtained from high pressure air and is independent of the current to be interrupted.

Disadvantages.

The use of air as the arc quenching medium offers the following disadvantges :

(i) The air has relatively inferior arc extinguishing properties.

(ii) The air-blast circuit breakers are very sensitive to the variations in the rate of rise of restriking voltage.

(iii) Considerable maintenance is required for the compressor plant which supplies the air-blast. The air blast circuit breakers are finding wide applications in high voltage installations. Majority of the circuit breakers for voltages beyond 110 kV are of this type.

Types of Air-Blast Circuit Breakers

Depending upon the direction of air-blast in relation to the arc, air-blast circuit breakers are classified into :

(i) Axial-blast type in which the air-blast is directed along the arc path.

(ii) Cross-blast type in which the air-blast is directed at right angles to the arc path.

(iii) Radial-blast type in which the air-blast is directed radially.

(i) Axial-blast air circuit breaker.

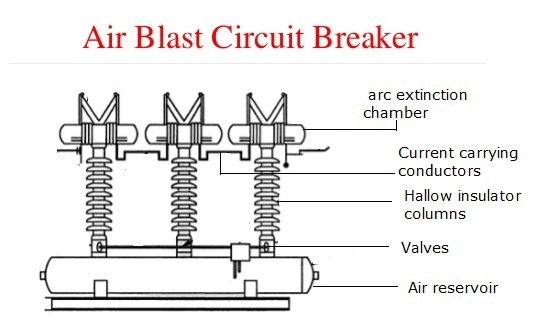

The fixed and moving contacts are held in the closed position by spring pressure under normal conditions. The air reservoir is connected to the arcing chamber through an air valve. This valve remains closed under normal conditions but opens automatically by the tripping impulse when a fault occurs on the system.

When a fault occurs, the tripping impulse causes opening of the air valve which connects the circuit breaker reservoir to the arcing chamber. The high pressure air entering the arcing chamber pushes away the moving contact against spring pressure. The moving contact is separated and an arc is struck. At the same time, high pressure air blast flows along the arc and takes away the ionised gases along with it. Consequently, the arc is extinguished and current flow is interrupted. It may be noted that in such circuit breakers, the contact separation required for interruption is generally small (1·75 cm or so). Such a small gap may constitute inadequate clearance for the normal service voltage. Therefore, an isolating switch is incorporated as a part of this type of circuit breaker. This switch opens immediately after fault interruption to provide the necessary clearance for insulation.

(ii) Cross-blast air breaker.

In this type of circuit breaker, an air-blast is directed at right angles to the arc. The cross-blast lengthens and forces the arc into a suitable chute for arc extinction.When the moving contact is withdrawn, an arc is struck between the fixed and moving contacts. The high pressure cross-blast forces the arc into a chute consisting of arc splitters and baffles. The splitters serve to increase the length of the arc and baffles give improved cooling. The result is that arc is extinguished and flow of current is interrupted. Since blast pressure is same for all currents, the inefficiency at low currents is eliminated. The final gap for interruption is great enough to give normal insulation clearance so that a series isolating switch is not necessary.

Nice blog on Industrial Engineering Knowledge eaton mcb gives good performance on all Electricals.

ReplyDelete