circuit Breakers classifications

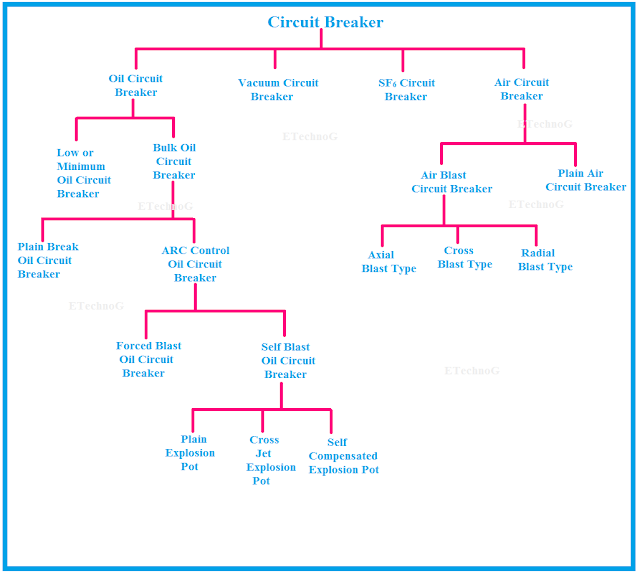

Classification of Circuit Breakers

There are several ways of classifying circuit breakers. However, the most general way of classification is based on the medium used for arc extinction. The medium used for arc extinction is usually oil, air, sulfur hexafluoride (SF6) or vacuum. Accordingly, circuit breakers may be classified into(i) Oil circuit breakers which employ some insulating oil (e.g., transformer oil) for arc extinction.

(ii) Air-blast circuit breakers in which high-pressure air-blast is used for extinguishing the arc.

(iii) Sulfur hexafluoride circuit breakers in which sulfur hexafluoride (SF6) gas is used for arc extinction.

(iv) Vacuum circuit breakers in which vacuum is used for arc extinction.

Each type of circuit breaker has its own advantages and disadvantages. In the following sections, we shall discuss the construction and working of these circuit breakers with special emphasis on the way the arc extinction is facilitated.

Oil Circuit Breakers

In such circuit breakers, some insulating oil (e.g., transformer oil) is used as an arc quenching medium. The contacts are opened under oil and an arc is struck between them. The heat of the arc evaporates the surrounding oil and dissociates it into a substantial volume of gaseous *hydrogen at high pressure. The hydrogen gas occupies a volume about one thousand times that of the oil decomposed. The oil is, therefore, pushed away from the arc and an expanding hydrogen gas bubble surrounds the arc region and adjacent portions of the contacts (See Fig. 19.2). The arc extinction is facilitated mainly by two processes. Firstly, the hydrogen gas has high heat conductivity and cools the arc, thus aiding the de-ionization of the medium between the contacts. Secondly, the gas sets up turbulence in the oil and forces it into the space between contacts, thus eliminating the arcing products from the arc path. The result is that the arc is extinguished and circuit current †interrupted.

Advantages.

The advantages of oil as an arc quenching medium are :(i) It absorbs the arc energy to decompose the oil into gases which have excellent cooling properties. Mainly hydrogen gas is produced

(ii) It acts as an insulator and permits smaller clearance between live conductors and earthed components.

(iii) The surrounding oil presents a cooling surface in close proximity to the arc.

(i) It is inflammable and there is a risk of a fire.

(ii) It may form an explosive mixture with air

(iii) The arcing products (e.g., carbon) remain in the oil and its quality deteriorates with successive operations. This necessitates periodic checking and replacement of oil.

(iii) The surrounding oil presents a cooling surface in close proximity to the arc.

Disadvantages.

The disadvantages of oil as an arc quenching medium are :(i) It is inflammable and there is a risk of a fire.

(ii) It may form an explosive mixture with air

(iii) The arcing products (e.g., carbon) remain in the oil and its quality deteriorates with successive operations. This necessitates periodic checking and replacement of oil.

Air-Blast Circuit Breakers

These breakers employ a high pressure *air-blast as an arc quenching medium. The contacts are opened in a flow of air-blast established by the opening of blast valve. The air-blast cools the arc and sweeps away the arcing products to the atomsphere. This rapidly increases the dielectric strength of the medium between contacts and prevents from re-establishing the arc. Consequently, the arc is extinguished and flow of current is interrupted.Advantages.

An air-blast circuit breaker has the following advantages over an oil circuit breaker:(i) The risk of fire is eliminated.

(ii) The arcing products are completely removed by the blast whereas the oil deteriorates with successive operations; the expense of regular oil replacement is avoided.

(iii) The growth of dielectric strength is so rapid that final contact gap needed for arc extinction is very small. This reduces the size of the device.

(iv) The arcing time is very small due to the rapid build up of dielectric strength between contacts. Therefore, the arc energy is only a fraction of that in oil circuit breakers, thus resulting in less burning of contacts.

(v) Due to lesser arc energy, air-blast circuit breakers are very suitable for conditions where frequent operation is required.

(vi) The energy supplied for arc extinction is obtained from high pressure air and is independent of the current to be interrupted.

Disadvantages.

The use of air as the arc quenching medium offers the following disadvantges :(i) The air has relatively inferior arc extinguishing properties.

(ii) The air-blast circuit breakers are very sensitive to the variations in the rate of rise of restriking voltage.

(iii) Considerable maintenance is required for the compressor plant which supplies the air-blast. The air blast circuit breakers are finding wide applications in high voltage installations. Majority of the circuit breakers for voltages beyond 110 kV are of this type.

Sulphur Hexaflouride Circuit Breakers

In such circuit breakers, sulphur hexaflouride (SF6) gas is used as the arc quenching medium. The SF6 is an electro-negative gas and has a strong tendency to absorb free electrons. The contacts of the breaker are opened in a high pressure flow of SF6 gas and an arc is struck between them. The conducting free electrons in the arc are rapidly captured by the gas to form relatively immobile negative ions. This loss of conducting electrons in the arc quickly builds up enough insulation strength to extinguish the arc. The SF6 circuit breakers have been found to be very effective for high power and high voltage service. Construction.It consists of fixed and moving contacts enclosed in a chamber (called arc interruption chamber) containing SF6 gas. This chamber is connected to SF6 gas reservior. When the contacts of breaker are opened, the valve mechanism permits a high pressure SF6 gas from the reservoir to flow towards the arc interruption chamber. The fixed contact is a hollow cylindrical current carrying contact fitted with an arc horn. The moving contact is also a hollow cylinder with rectangular holes in the sides to permit the SF6 gas to let out through these holes after flowing along and across the arc. The tips of fixed contact, moving contact and arcing horn are coated with copper-tungsten arc resistant material. Since SF6 gas is costly, it is reconditioned and reclaimed by suitable auxiliary sytem after each operation of the breaker. Working. In the closed position of the breaker, the contacts remain surrounded by SF6 gas at a pressure of about 2·8 kg/cm2. When the breaker operates, the moving contact is pulled apart and an arc is struck between the contacts. The movement of the moving contact is synchronised with the opening of a valve which permits SF6 gas at 14 kg/cm2 pressure from the reservoir to the arc interruption chamber. The high pressure flow of SF6 rapidly absorbs the free electrons in the arc path to form immobile negative ions which are ineffective as charge carriers. The result is that the medium between the contacts quickly builds up high dielectric strength and causes the extinction of the arc. After the breaker operation (i.e., after arc extinction), the valve is closed by the action of a set of springs.Advantages.

Due to the superior arc quenching properties of SF6 gas, the SF6 circuit breakers have many advantages over oil or air circuit breakers. Some of them are listed below :(i) Due to the superior arc quenching property of SF6, such circuit breakers have very short arcing time.

(ii) Since the dielectric strength of SF6 gas is 2 to 3 times that of air, such breakers can interrupt much larger currents.

(iii) The SF6 circuit breaker gives noiselss operation due to its closed gas circuit and no exhaust to atmosphere unlike the air blast circuit breaker.

(iv) The closed gas enclosure keeps the interior dry so that there is no moisture problem.

(v) There is no risk of fire in such breakers because SF6 gas is non-inflammable.

(vi) There are no carbon deposits so that tracking and insulation problems are eliminated.

(vii) The SF6 breakers have low maintenance cost, light foundation requirements and minimum auxiliary equipment.

(viii) Since SF6 breakers are totally enclosed and sealed from atmosphere, they are particularly suitable where explosion hazard exists e.g., coal mines.

(ii) Since SF6 gas has to be reconditioned after every operation of the breaker, additional equipment is requried for this purpose.

(v) There is no risk of fire in such breakers because SF6 gas is non-inflammable.

(vi) There are no carbon deposits so that tracking and insulation problems are eliminated.

(vii) The SF6 breakers have low maintenance cost, light foundation requirements and minimum auxiliary equipment.

(viii) Since SF6 breakers are totally enclosed and sealed from atmosphere, they are particularly suitable where explosion hazard exists e.g., coal mines.

Disadvantages

(i) SF6 breakers are costly due to the high cost of SF6.(ii) Since SF6 gas has to be reconditioned after every operation of the breaker, additional equipment is requried for this purpose.

Applications.

A typical SF6 circuit breaker consists of interrupter units each capable of dealing with currents upto 60 kA and voltages in the range of 50—80 kV. A number of units are connected in series according to the system voltage. SF6 circuit breakers have been developed for voltages 115 kV to 230 kV, power ratings 10 MVA to 20 MVA and interrupting time less than 3 cycles.Vacuum Circuit Breakers (VCB)

In such breakers, vacuum (degree of vacuum being in the range from 10−7 to 10−5 torr) is used as the arc quenching medium. Since vacuum offers the highest insulating strength, it has far superior arc quenching properties than any other medium. For example, when contacts of a breaker are opened in vacuum, the interruption occurs at first current zero with dielectric strength between the contacts building up at a rate thousands of times higher than that obtained with other circuit breakers. Principle. The production of arc in a vacuum circuit breaker and its extinction can be explained as follows : When the contacts of the breaker are opened in vacuum (10−7 to 10−5 torr), an arc is produced between the contacts by the ionisation of metal vapours of contacts*. However, the arc is quickly extinguished because the metallic vapours, electrons and ions produced during arc rapidly condense on the surfaces of the circuit breaker contacts, resulting in quick recovery of dielectric strength. The reader may note the salient feature of vacuum as an arc quenching medium. As soon as the arc is produced in vacuum, it is quickly extinguished due to the fast rate of recovery of dielectric strength in vacuum. Construction. It consists of fixed contact, moving contact and arc shield mounted inside a vacuum chamber. The movable member is connected to the control mechanism by stainless steel bellows. This enables the permanent sealing of the vacuum chamber so as to eliminate the possibility of leak. A glass vessel or ceramic vessel is used as the outer insulating body. The arc shield prevents the deterioration of the internal dielectric strength by preventing metallic vapours falling on the inside surface of the outer insulating cover. Working. When the breaker operates, the moving contact separates from the fixed contact and an arc is struck between the contacts. The production of arc is due to the ionisation of metal ions and depends very much upon the material of contacts. The arc is quickly extinguished because the metallic vapours, electrons and ions produced during arc are diffused in a short time and seized by the surfaces of moving and fixed members and shields. Since vacuum has very fast rate of recovery of dielectric strength, the arc extinction in a vacuum breaker occurs with a short contact separation (say 0·625 cm).Advantages.

Vacuum circuit breakers have the following advantages :(i) They are compact, reliable and have longer life.

(ii) There are no fire hazards.

(iii) There is no generation of gas during and after operation.

(iv) They can interrupt any fault current. The outstanding feature of a VCB is that it can break any heavy fault current perfectly just before the contacts reach the definite open position.

(v) They require little maintenance and are quiet in operation.

(vi) They can successfully withstand lightning surges.

(vii) They have low arc energy.

(viii) They have low inertia and hence require smaller power for control mechanism.

No comments